(This post is based on "Space-Age Flavors and Population Bombs: Flavor Research, Synthetic Foods, and Technologies of Abundance in Cold War America," a paper I presented at the end of April at "The Invention of Food," a conference hosted by the Institute for Historical Research at UTAustin.)

Blog! It's been so long! So much has happened since I last ruminated within these margins! I finally finished my dissertation, and defended it at the beginning of May, so Doctor Berenstein is officially in, and ready to address all sorts of metaphysical and spiritual ailments related to flavor, its authenticity, or its absence.

In my first post-PhD-in-flavor blog post, I wanted to visit one of the food stories I didn't get to tell in my dissertation, a story from the period of time dubbed the "era of flavor" by one postwar food technologist: the 1960s. The arrival of the "era of flavor" depended, in part, on things without flavor — on bland materials and insipid food subtrates that were, quite literally, made to be flavored.

This post is about one of those bland materials, a new kind of high-tech substance: spun soy protein. In the late 1960s, spun soy protein was a "food of the future," one of a new generation of textured vegetable proteins, developed as a delicious solution for a world that seemed on the verge of a catastrophic protein shortage. But although the spun protein future never quite arrived, its legacy is still with us today.

Does this proteinaceous soybean gauze hold the potential to save the world, without sacrificing deliciousness? Read on to find out!

Make Way For the Soymobile

This story really begins in the 1930s, with Henry Ford, automaker, soybean believer, chemurgist. "Chemurgy" was a sort of technocratic alliance between agriculturalists and industrialists, a movement that perceived America’s farmland as a source not only of food, but also of raw materials for modern industry. Chemists devised new uses for agricultural surplus and farm wastes: wallpaper and glue from peanut shells; synthetic rubbers from soybeans and corn; ethanol fuels from corn, barley, sweet potatoes, and Jerusalem artichokes; milkweed-stuffed life preservers. These new industrial markets were supposed to keep farmers afloat during the lean years of the Depression, while also providing a foundation for national self-sufficiency and continuing prosperity in a world that increasingly seemed on the brink of another war.

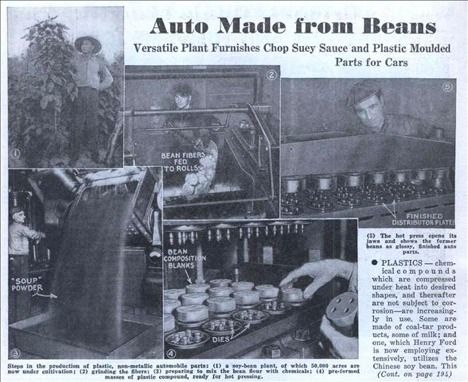

From a 1934 issue of Science and Mechanics. Image source: Treehugger blog.

“Everything pertaining to an automobile has its origin in the earth,” explained one newspaper article in 1936, describing the Ford Motor Company's chemurgic research efforts. “There is no need, as Mr. Ford sees it, to exhaust the mines and forests if the material required can be grown on the farm.” Ford envisioned efficient farm-factories, where renewable materials could be grown, harvested, and processed into plastics, synthetic rubbers, and fuels, a future where his company would one day be in the business of “growing cars out of the ground.”

In particular, Ford placed a big bet on soy. Soy had been grown commercially in the U.S. since the 1920s, largely as a source of oils and animal feed, but Ford was particularly interested in its uses in phenolic plastics. The scientists at the soybean research laboratory at Ford's vast industrial compound in Dearborn, Michigan were tasked with developing new uses for soy oils and soy meals: in plastics, resins, lubricants, and fuels. Ford automobiles in the 1930s increasingly used soy-based materials in paints and shock absorbers, and featured soy-plastic buttons, knobs, and seats. This project culminated with the “soybean car,” a 1941 prototype whose chassis was (allegedly) made entirely from a soy-based plastic resin. Although the focus was on industrial research, Ford did not entirely ignore the edible potential of the soybean. A vegetarian, Ford was an avid believer in the vital powers of soyfoods. A smorgasborg of soyfoods — including soybean “steaks,” soy milk, and soybean coffee — accompanied the soybean car’s debut.

Robert Boyer (left) and Henry Ford, with the soybean car. Is Boyer crinkling his nose at its mortuary smell?

One of the chemists working at the soy research laboratory in Dearborn was Robert Boyer. Boyer had developed a method for using protein extracted from soy meal— gritty, cakey stuff left over after the production of soy oil — and spinning it into fibers, which could be woven into textiles. Ford sometimes wore a suit made from this soy-wool blend — though the fabric, apparently, had a tendency to split. (If you bend over in a soy-wool suit, do so carefully.) The fiber was more practical in haberdashery; felted soy-rabbit fur supposedly made an excellent toque.

Ford died in 1946, and the Ford Model Soy never made it to production — derailed first by the Second World War, then by petrochemical-based plastics. (And also, perhaps, by its indelible “mortuary smell,” traces of formaldehyde that lingered in the resin.)

Boyer’s soy fibers, however, did persist — not as fabric, but as food.

Henry Ford in his soy-blend suit, seated carefully on a haystack. Image from Greg Grandin's book, Fordlandia.

Continuous Ribbons of Pure Protein

Boyer continued to work on spun proteins after the war, hoping to find a way to create a nutritious edible fiber from material destined for livestock feed or the trash heap. First, though, there was the problem of taste. Earlier attempts to make human foods out of defatted protein-rich soy meal had faltered; traces of soluble carbohydrates and other compounds gave the substance a disagreeably bitter “beany” flavor, and contributed to its unfortunate reputation for causing digestive distress. The introduction of highly refined food-grade soy protein isolates in the 1950s made it possible to produce spun soy fiber without the bitterness or the farting. Purified soy protein isolate produced fibers which were pale, bland, odorless, and highly digestible, an edible blank canvas primed for the application of flavor effects.

Boyer received a patent for his protein-spinning process in the early 1950s, which he then licensed to various food manufacturers. The first taker was Worthington Foods, an Ohio company that made vegetarian foods primarily for Seventh-Day Adventist communities. Worthington introduced the first commercial spun soy protein product: Fri-Chik, chicken-flavored pre-cooked heat-and-serve patties that were available frozen or in cans.

Larger food manufacturing and agribusiness companies, including Archer-Daniels-Midland, Swift & Co., and General Foods, licensed Boyer’s patent. But no company invested as much in the potential of spun protein as General Mills, which put Boyer's method at the heart of its synthetic foods research program. At its peak in the 1960s, General Mills’ Isolated Protein Research & Development Program employed more than 50 scientists and technicians, working on ways to scale up spun protein production and develop new kinds of commercial products.

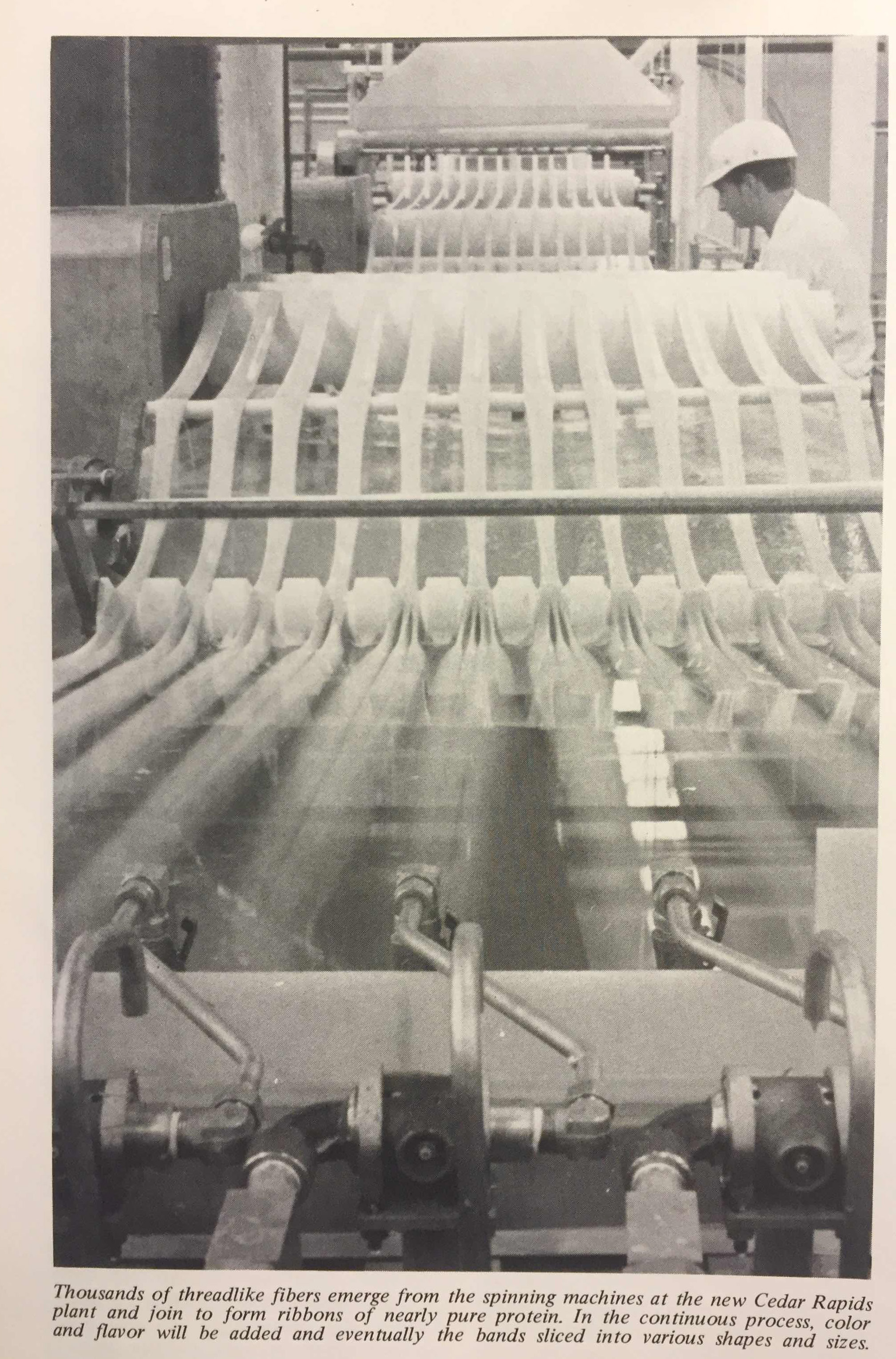

General Mills' protein-spinning plant in Cedar Rapids. Image source: Progress Thru Research, vol 24, no 2, 1970-1.

In 1969, General Mills opened a new, multimillion-dollar, state-of-the-art spun-protein plant in Cedar Rapids, Iowa. Iowa was the nation’s largest soybean producer, and Cedar Rapids was a hub of advanced technical knowledge. Collins Radio, the principal supplier of radio and navigational equipment to the military and to NASA, had its headquarters in the city. The same community of highly trained electrical and mechanical engineers who produced the machines that guided satellites and spacecraft were invited to find jobs at the General Mills plant, designing, assembling, and maintaining the systems that would weave the foods of the future from humble defatted soymeal.

This description of protein-spinning that follows is based on accounts of General Mills’ operations. First, refined soy protein isolate was blended into a proteinaceous slurry with the viscosity of honey; this was called the “dope.” The dope was then “spun”: pumped through a spinneret — a plate dotted with tiny holes — in an acid bath, which coagulated the proteins into fibrils. These fibrils were then stretched, becoming finer and stronger, to form continuous ribbons of protein.

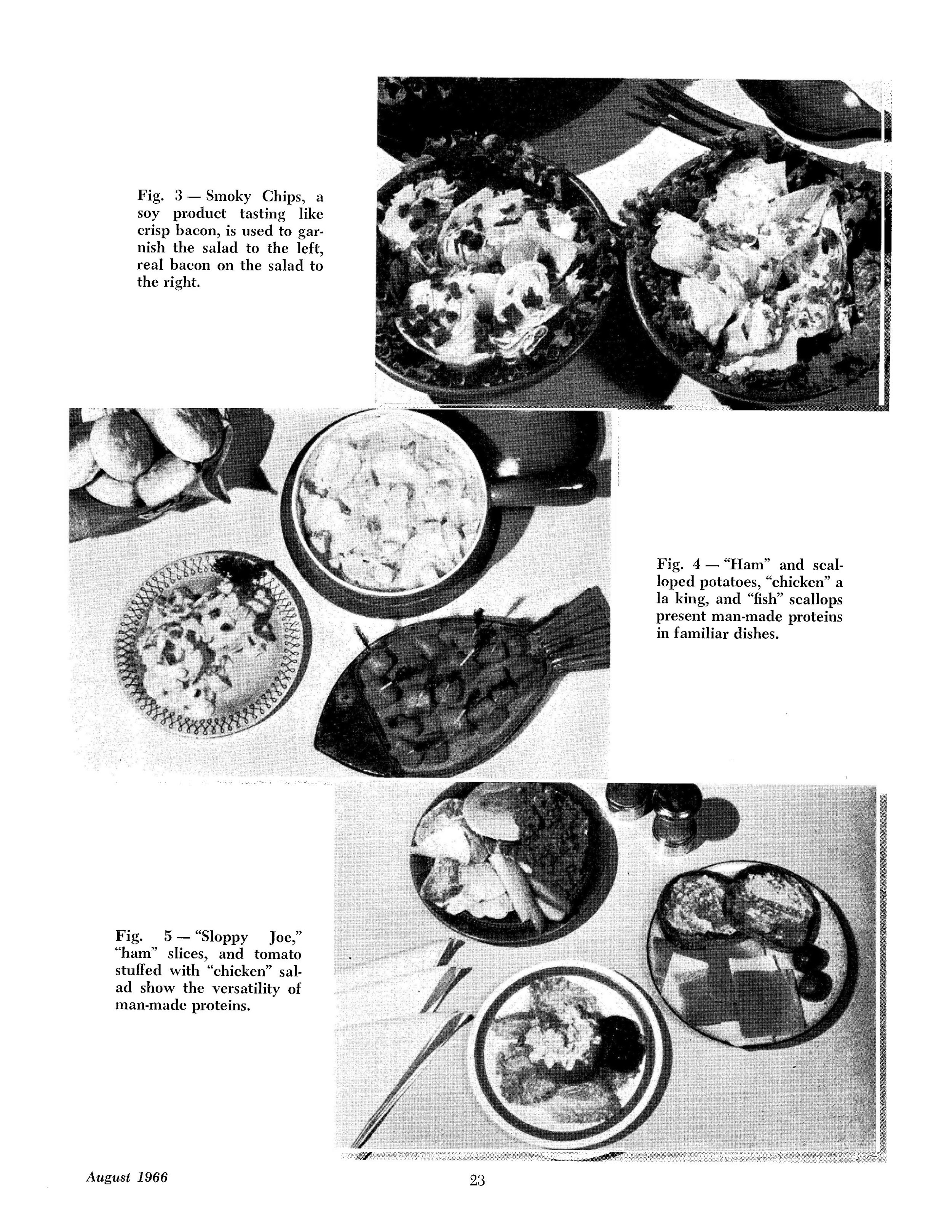

These ribbons were edible, but they were not yet food. At this stage, the fibrils were blended with fats, supplemental nutrients, colorings, flavorings, binders, and stabilizers, and molded into their final form: slices, crumbles, cubes, or chunks. These could then be dehydrated, giving them an almost limitless shelf-life; or incorporated into packaged “convenience” foods, frozen or canned, ready to heat and serve.

Almost every aspect of spun protein foods could be designed and shaped at will. By manipulating the thinness and length of the fibrils, as well as their orientation in the warp and woof of the food matrix, texture, tenderness, and chewiness could be calibrated to deliver the desired “bite.” Advances in flavor chemistry in the 1960s had illuminated the compounds that contributed to the distinctive flavors of raw and cooked meats; these new insights into the molecular relations of savoriness were incorporated into the flavorings that added sizzle and smoke to Kosher "bacon" and roastedness to Lenten "chicken." The nutritional profile and calorie count of spun protein foods could be tailored for different dietary requirements, such as those of diabetics, people with high cholesterol, or those on other special medical diets.

Bontrae manufacturing flowchart. Bontrae was General Mills' proprietary name for their spun protein substance. [Click to expand.] Image source: A.D. Odell, "Meat Analogues: A New Food Concept," Cornell H.R.A. Quarterly, August 1966. Odell headed General Mills' Isolated Protein research program at their Minneapolis R&D center.

“Boyer’s process makes it possible for the first time to fabricate food products according to a pre-set specification,” explained one marketing expert in 1969. This was food as plastic — moldable, malleable, versatile, made to spec, and shaped into virtually any imaginable form to suit any imaginable need. All that, and at a price (somewhat) below that of meat.

But spun protein’s plasticity and absence of inherent qualities also raised fundamental questions about its identity. What, exactly, was it? Was it imitation meat, meatless meat? Or was it an entirely new category of food, something unheralded? These were critical questions at a time when the FDA’s primary tool for regulating the food supply was by enforcing standards of identity, which minutely dictated the contents of food products and the names under which they could be sold.

The varied guises of spun protein foods. Image source: A.D. Odell, "Meat Analogues — A New Food Concept," Cornell H.R.A. Quarterly, August 1966.

General Mills was, accordingly, cautious about how they referred to their new product. On the one hand, if the meat industry perceived spun soy protein as a threat, they could potential mobilize Congress and government agencies to force them to label their products “imitation,” which would doubtless affect both its reputation and sales. On the other hand, General Mills did not necessarily want to advertise that their product was made from soy, which had a less than appetizing reputation among postwar American consumers. Americans associated soy with animal feeds, not human foods, and the dispiriting memory of wartime soy-meats was still nauseatingly vivid for many. “Abortive attempts in the past to market soy to the fickle U.S. consumer have caused food companies, despite their optimism, to move cautiously,” warned the marketing expert in 1969. “One or two fumbled marketing efforts could petrify consumer resistance.”

Advertisement and coupon for Bontrae from Louisville (KY) Courier-Journal, August 14, 1975. [Click to expand.] The advertisement emphasizes the savings, convenience, and health benefits that made Bontrae a better choice than actual meat, while promising consumers that they would not be sacrificing flavor. "They taste so much like real chicken and ham, we're willing to bet only your wallet can tell the difference."

General Mills ultimately invented a name for their spun protein fiber, "Bontrae" — charmless pseudo-Latin cleansed of every hint of soy, utterly unsuggestive, perhaps deliberately. For a time, the company (unsuccessfully) petitioned the FDA to recognize Bontrae as a new kind of substance, rather than an imitation of other foods. “Bontrae foods technology creates products which have considerable similarity to traditional foods, such as meat, but these products are, in the truest sense, neither synthetic nor imitation,” explained William Reynolds, General Mills' Vice President for Technical Development, in 1969. To require Bontrae foods to be labeled "imitation" would be misleading. Neither synthetic nor imitation, Bontrae was Bontrae, and Bontrae could be anything.

In practice, however, General Mills used Bontrae in two distinct categories of products: as "meat analogs," and as meat extenders.

Meat analogs were entirely fabricated products, complete on their own rather than ingredients in other foods. General Mills' first commercial Bontrae product — Bac*Os, introduced in late 1965 — is an example of a meat analog. Bac*Os was a hit, even if its substance remained something of a mystery. It also found its way into other products, such as Skippy Peanut Butter with Smokey Crisps, and Henri's Smokey Bits Salad Dressing — those smokey crisps and bits were spun protein. But Bac*Os was a condiment, not the cornerstone of a meal, and General Mills had bigger plans. In the early 1970s, General Mills introduced Bontrae chicken and Bontrae ham, urging consumers to look for these products at the fresh meat counter, and to use them in recipes instead of the real thing.

Bontrae's second use was as a meat extender, blended with ground beef to reduce meal costs without diminishing nutritional value. Initially, the main market for textured protein meat extenders were institutions, not households. When the National School Lunch Program approved the addition of textured soy protein to meat dishes in 1971, it was a boon to spun protein manufacturers like General Mills and also makers of a competing product, extruded textured soy flours. (How many of my beloved elementary school sloppy joes were bulked with textured soy?) But a consumer market for these products was envisioned as well. When meat prices spiked in the early 1970s, leading to a consumer boycott in 1973 to protest high costs, textured protein-beef blends were test-marketed in grocery stores. If prices for the real thing continued to rise, General Mills hoped that shoppers would be willing to swap some of their beef for Bontrae.

Let Them Eat Bac*Os

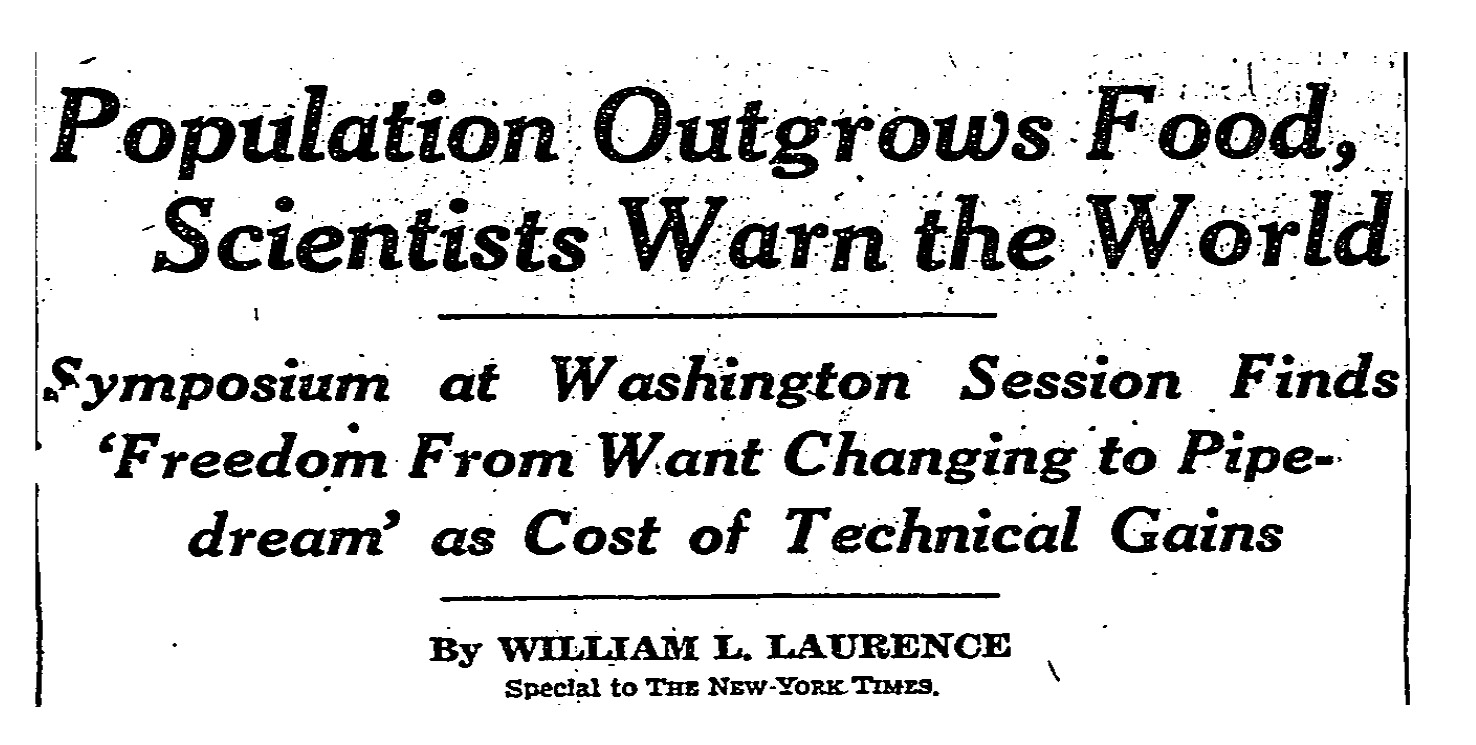

The production of spun protein foods was not just a commercial venture. It was presented as an urgent global necessity. Since the end of the Second World War, a growing chorus of scientists, leaders, and experts warned of an impending planetary crisis. The world's population was expanding exponentially, but its resources were only increasing arithmetically. The "population bomb," as it came to be called, would lead to the kind of catastrophic food shortages predicted more than a century earlier by economist Robert Malthus.

In particular, the global food crisis was depicted as a critical shortage of one macronutrient: protein. This aspect of the crisis was already evident in the developing world; in the early 1960s, it was widely reported that half the world's population was undernourished. Images of brown and black children, bellies distended by the protein-deficiency disease kwashiorkor, became the familiar symbols of global hunger.

Scientists at the 1948 meeting of the American Association for the Advancement of Science fretted that technological advances . New York Times, September 15, 1948.

New agricultural technologies, chemical fertilizers and pesticides, could only go so far, experts warned. And coercive population control measures were out of step with the liberal values that the United States aspired to project upon the Cold War geopolitical stage. For many who studied the problem, the best hope for humanity seemed to lie not in finding new land to cultivate, nor in increasing the yield per acre, but in developing new sources of food, and especially, new sources of protein. Chlorella algae farms, protein powders ground from the by-catch ("trash fish")of the Atlantic fisheries , proteins and fats synthesized from petrochemicals: all of these were considered as possible solutions.

The technology of protein spinning was deeply embedded in this world-saving discourse; its versatility was crucial to estimates of its potential. Soy was not necessary; edible protein could be spun from the defatted meal of many oilseed crops, such as cottonseed, peanut, safflower, and alfalfa. “Indigenous, often wasted protein resources in technologically underdeveloped countries could be tapped and utilized,” explained A.D. Odell, the head of General Mills’ Isolated Protein Program, in a 1965 article.

In other words, protein spinning technology could be imported into countries where it was most needed, and adapted to the task of salvaging untapped local protein supplies. Even better, its products could be molded into the familiar guise of traditional foods. As C.G. King, the head of the Nutrition Foundation, explained in a 1961 speech to the food industry, when developing products for global food aid, “one has to be very sensitive to their flavor traditions, not our flavor traditions.” Fish protein concentrates, dried chlorella algae, and other supplemental nutritional aids were developed to deliver calories or protein, but encountered huge resistance when it came to their taste. This did not have to be the case with spun protein, which could be made to conform with cultural ideas of deliciousness. “Local taste preferences are readily met with," wrote Odell, "and acceptance would seem assured, due to the gustatorial gratification which they provide, as opposed to a powder or amorphous concentrate.” Unlike of a packet of goo or a fishy, protein-boosted flour, spun protein could offer both salvation and gratification.

I have found no evidence that spun protein products were ever used in global food aid (which doesn't mean they weren't; my research into this is far from exhaustive.) In the 1960s, hunger and malnutrition was not yet widely recognized as a problem within the United States; its victims were elsewhere, distant receptacles of pity in the developing world. Yet the world protein shortage is repeatedly, insistently invoked, both in accounts of General Mills' spun protein research program and Cedar Rapids factory, as well as in the synthetic products it spawned.

Advertisement for General Mills products, featuring Betty Crocker, trustworthy symbol of unfussy competence, touting Bontrae as "a food of the future made with vegetable protein." From Woman's Day, March 1969.

Man: "What's Bontrae?"

General Mills: "It's General Mills' name for a food of the future made with vegetable protein."

Under the familiar gaze of Betty Crocker, a 1969 advertisement for Bac*Os explained Bontrae not in terms of its contents, but in terms of its commitments: “General Mills’ investment in this important new food is your assurance of another natural source of high quality protein for your children and their children and the world.”

Is this what it means for something to be a “food of the future"? A technological novelty, but also a necessity or even an inevitability; contributing to a better world while delivering convenience, value, and quality to the consumer.

The homemaker sprinkling Bac*Os over deviled eggs or chicken-noodle casserole was thus at the leading edge of a wave of innovation that could, quite literally, save humanity. With each smoky, scarlet flake, she claimed her seat at the table of the new food future, one that encompassed not only her own family, but her children’s children, succeeding generations, and the children of the world.

The End of the End of the World

The spun-protein soyfood future did not arrive as planned. General Mills abruptly shut down its Cedar Rapids spun protein operations in 1976, after Bontrae sales failed to materialize. The company sold its protein spinning equipment to Dawson Mills, a Minnesota food processor, and licensed the Bontrae process to Central Soya of Illinois. Both companies would subsequently abandon spun protein manufacturing in the early 1980s.

I spoke with a former maintenance engineer at General Mills, who was involved in disassembling the spun protein production line and converting the plant to cereal manufacturing. (Honey Nut Cheerios, General Mills’ perennial best-seller, was first produced there in 1979.) Forty years later, he still marveled at the sophistication of the machinery that he had taken apart. The spinnerets were platinum, he recalled, and so finely perforated that they were translucent when you held them up to the light.

He had had a chance to taste some of the Bontrae foods, and told me that the ham- and bacon- flavored products were actually quite good. Employees at the time blamed Bontrae’s failure on its use as a “meat extender,” blended with ground beef to reduce food costs without diminishing nutritional value. Perhaps inevitably, institutional food service customers — hospitals, nursing homes, and school dining halls — tended to ignore the recommended ratio and overload the mixture with soy, with dismal results for eaters and for the product’s reputation.

Although soy protein products continued to be manufactured on a large scale, most of these were textured soy flours, such as Archer-Daniel-Midland’s Textured Vegetable Protein (TVP), produced by thermoplastic extrusion — cheaper to manufactured than spun protein, but also less versatile. (At some point, General Mills also began producing Bac*Os by extrusion, rather than using spun protein.) With few exceptions, textured soy flours generally did not aim for mass markets, but sought a foothold as unsung, imperceptible ingredients in other foods; as components of animal feed; or in niche vegetarian and health-food contexts.

Despite its lack of commercial success, I think Bontrae (and spun protein) was a turning point, prefiguring the efforts of today's synthetic food purveyors, companies such as Impossible Foods, Beyond Meat, and Hampton Creek. These are start-up-style ventures that fashion themselves not as infant versions of stodgy old-school food processors like General Mills, but as tech companies that just happen to make food. (In a certain sense, using their image as tech companies to launder their work as food processors.) But, as this story shows, food processors such as General Mills are also, perhaps fundamentally, tech companies. Bontrae was food as technology.

It’s difficult for us now to imagine just how radical it was to conceive of Bontrae as a mass-market product, something that the average supermarket shopper pushing her groaning cart down the aisles of Kroger's or the A&P, circa 1973, may have paused to compare with livid lozenges of chicken breasts or cellophane-wrapped pork chops. Consider that for most of modern history, “fake” meats (and other “imitation” foods) were low-status, undesirable goods. They were associated either with the deprivations of war or of extreme poverty, or found limited sales among vegetarians and others with dietary restrictions. Bontrae as a meat extender fit into this conceptual model, a means of managing in straitened circumstances, making do with less.

But Bontrae, as a meat analog, was made to be tasted. Its deliberately designed texture and flavor complemented its various functional advantages — its ease of preparation, alleged nutritional virtues, stability, and versatility. Its lower cost compared to meat, in this scenario, was a virtue that was also a weakness, an advantage that also confirmed the image of cheapness and lower quality that consumers were prone to suspect it of.

In this way, Bontrae imperfectly embodied a way of thinking about synthetic foods that was just beginning to emerge — not as substitutes for traditional commodities, but as innovative technologies with distinct virtues and unique possibilities. As Odell, the head of General Mills' isolated protein program, put it in 1969: “There are almost no theoretical limitations to the scope of reproducibility or to the creation of new, never before considered categories for the future… Perhaps it is not too bizarre to speculate that a major future role of animal tissues will be as flavoring substances for vegetable derived tissues.”

One day, perhaps, meat would be nothing but a sort of seasoning, sprinkled like Bac*Os over a varied and limitless Bontrae cuisine, which offered unimagined pleasures and savory sensations to a world amply sustained by spun vegetable proteins.

This line of reasoning did not prevail in the 1970s. Worries about the “population bomb” faded as the predicted cataclysm failed to materialize. American meat did not become rarer and more expensive; it became more abundant and cheaper. But even as the terms in which we understand the global food problem have shifted from "population" to "climate," we (meaning, Western, prosperous eaters) continue to be attuned to the possibility of crisis. General Mills had to connect the dots between its synthetic food product and the dwindling global supply of protein. Today, messages about the virtues of “sustainability” are inescapable, ornamenting shopping bags, reusable water bottles, and corporate and sincere swag, even as the White House has staked out a stubbornly unfashionable position on the matter.

The new generation of “meat analogs,” the burgers that bleed and the tender chickeny strips of pea protein, are Bontrae’s heirs. These meatless meats are not designed primarily for those who cannot or will not eat meat because of its cost or their scruples. As Patrick Brown, CEO of Impossible Foods, told Quartz earlier this year: “Our definition of success is: we score zero points if a vegan or vegetarian buys our burger. The more of a meat lover they are, the more they are our target customer.”

These exquisitely engineered technologies are foods of choice — and specifically, of the enlightened choice of economic elites. Perhaps one of the reasons that Impossible Foods and its ilk seem to be succeeding where Bontrae faltered is that these companies do not feel the need to undercut “real” meat on price. The value-add of the “socially responsible choice” is worth more to us now. We will pay for the luxury of moral righteousness, especially when we also do not have to pay a price in flavor.

The promise that connects Bontrae and Impossible Foods is this: we can have crisis without austerity. These foods of the future may be marked by necessity, but they aren’t the foods of last resort, the scraps we sustain ourselves with as we eke out our final days on a warming, crowded planet. These are foods designed for pleasure as well as sustenance, for convenience as well as survival.

FURTHER READING:

This only scratches the surface of soyfoods and textured vegetable protein history. This is a super fascinating topic, and I hope someone is working on a big beautiful book about it. For anyone who is interested in this (and why wouldn't you be?), there is an incredible online resource, the SoyInfo Center, the apparent lifework and labor of love of William Shurtleff and Akiko Aoyagi. These two assiduous and intrepid researchers have documented not only the cultural and agricultural history of soy cultivation and traditional soyfoods, but also its industrial and technological history. They have chosen to make a staggering amount of material freely available online, and I drew heavily on their work and documentation in putting this together.

For those of you who are looking for a broader consideration of "foods of the future," as well as algae burgers, and the perennial threat of a Malthusian crisis, I recommend Warren Belasco's 2006 book, Meals to Come: A History of the Future of Food.